According to OSHA, hot work activities involve “welding or cutting operations, use of spark-producing power tools, and chipping operations.” In general, open flames should be a major signal the hot work activities are in process. Hot work is an unavoidable part of many work environments, at least on occasion. The reason for special attention to hot work is that these activities involve fire hazards that are common sources of accidental ignition. A hot work permit system can help to identify and manage hot work operations so you can prevent fires, injuries, and property damage.

Risks Triggered by Hot Work

According to the NFPA’s report on Structure Fires Started by Hot Work, between 2014 and 2018, fire departments in the United States responded to an average of 4,580 structure fires each year involving hot work. Of those hot work fires, 57 percent occurred in or on non-home properties. The goal of a permitting system is to reduce hot work hazards in the workplace.

The risk of hot work involves all three parts of the fire triangle: oxygen, fuel, and an ignition source.

- Oxygen: Unsafe practices involving pure oxygen can cause oxygen enrichment (over 22 percent by volume) in the workplace.

- Fuel: Common fuels include construction materials such as wood, plastic, insulation, and roofing materials. Flammable materials and combustible liquids or gases like fuel, paint, and cleaning solvents can also provide fuel. And other incidental combustibles like rags, paper, cardboard, lumber, and furnishings are other common fuels for workplace fires.

- Ignition: Ignition occurs through the direct application of heat (welding, cutting, and burning) or indirect application of heat (such as heat conducted through metal surfaces to fuel sources on the other side, or sparks traveling to a distant fuel source).

Hot work operations are generally high-risk tasks that could affect the health and safety of the workers who are performing hot work as well as anyone else nearby.

When is a Hot Work Permit Necessary?

In most workplaces where hot work is undertaken from time to time, such as maintenance welding to fix a machine, a temporary hot work permit is required. Permits do not need to be issued when hot work operations are regularly performed in designated areas that have been cleared of hazards. For example, a hot work permit would not be necessary in a welding shop, because hot work precautions should always be in place in that type of designated area.

Standards That Apply to Hot Work

Are hot work permits required by OSHA? Yes, hot work procedures are covered by various OSHA standards, as well as ANSI standards, NFPA codes, and other fire prevention codes including state and local codes. Specific standards that address hot work include:

- NFPA 51B, Standard for Fire Prevention During Welding, Cutting, and Other Hot Work

- 29 CFR 1910 (Occupational Safety and Health Standards) Subpart Q (Welding, Cutting, and Brazing)

- 29 CFR 1926 (Safety and Health Regulations for Construction) Subpart J (Welding and Cutting)

- ANSI Z49.1, Safety in Welding, Cutting, and Allied Processes, 2012

35-Foot Rule for Hot Work

Many standards, including NFPA 51B, require a permit only under certain conditions, such as when it isn’t possible to secure a 35-foot radius clear of combustibles from the work task. However, it is highly advisable to use a hot work permit system for all hot work operations outside a designated hot work area.

How Does the Hot Work Permit System Work?

A hot work permit system requires that a supervisor issues a permit whenever hot work is undertaken outside a designated area. This supervisor also ensures that the requirements for the hot work area are met.

Once the permit has been obtained, a worker performs the task while a fire watcher stands by to address any emergent issues. Once work is completed, the supervisor is notified, and the fire watch continues for at least 30 minutes after the activity is completed.

Hot Work Control Measures to Keep Workers Safe

PPE Required to Perform Hot Work

The appropriate Personal Protection Equipment (PPE) must be used whenever hot work is conducted, including eye, face, and hand protection at a minimum. Attendants on hot work area monitoring must also be provided with appropriate PPE. Other PPE like boots, gloves, hard hats, fall protection, and protective garments may also be required by OSHA.

Hot Work Fire Watch Requirements

Fire watch requirements for any hot work operation are spelled out in section 3504.2 of the International Fire Code (IFC). First aid boxes and fire extinguishers should be available in any area where workers are performing hot work. Trained fire watch personnel must keep an eye on the entire hot work area during hot work operations and for a period of at least 30 minutes after completion of the work. That means that firefighting equipment must also be available in the hot work area and that someone trained in the use of fire extinguishers must be responsible to extinguish any spot fires and communicate an alarm.

Additional Precautions

Confined spaces enhance risk, so for enclosed vessels and confined spaces, a qualified person should check the atmosphere for oxygen content, combustibles or reactive gases, and toxic gases.

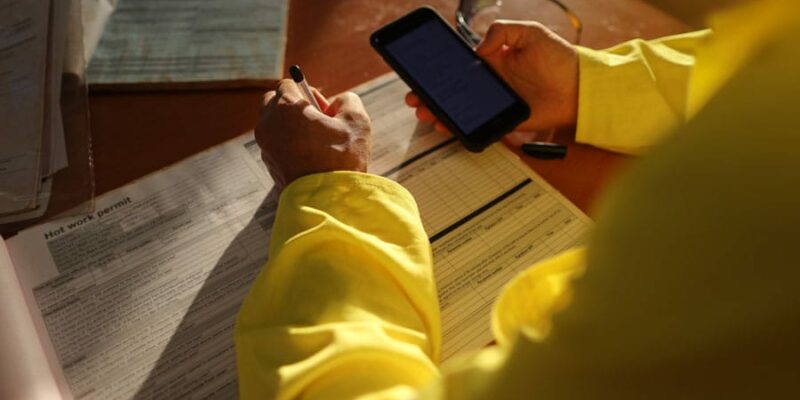

Hot Work Permit Requirements and Examples

Most hot work permits share a similar format, although some differences may be particular to the job site.

Parts of a Hot Work Permit

Generally, a hot work permit includes basic information about the work activity:

- date

- location

- work that will be undertaken

- time started and completed

- who is doing the work

- name and signature of the person authorizing the work permit (PAI)

- permit number

Hot Work Permit Checklist

In addition to the details about the hot work operation, a hot work permit usually includes a checklist that may or may not apply to every hot work permit. Items on the checklist may include:

- PPE Checklists

- Work Area Inspection

- Measures

- Closure of Permit

- Transfer Checklist

Hot Work Permit Example

Some organizations may use a standard form such as the general Hot Work Permit form provided by the National Fire Prevention Association. Such general forms may or may not meet the requirements of a local jurisdiction, so many organizations tailor the form to meet the requirements of their environment, processes, or other standards.

EMDS Offers Assistance with Hot Work Permit Compliance

By understanding the regulations, taking the proper safety precautions, and obtaining a valid hot work permit prior to beginning any task, employers can ensure their workers’ safety and protect themselves from legal liability.

EMDS offers hot work permit consulting to keep your business compliant with all the relevant safety standards for hot work in general industry or construction. Our safety compliance consultant helps ensure that procedures are in place to maintain compliance with OSHA hot work standards and other requirements so you can keep your employees and your property safe. In addition to consulting, EMDS also offers hot work permit training as part of its OSHA 10/30 Hour training programs.

Don’t wait. Take the time to understand your local laws and national regulations and ensure your company’s compliance today!