Equipment servicing and maintenance always adds a degree of risk to employee safety when the machine guards come off. The Occupational Safety and Health Administration (OSHA) recognizes that risk and provides a standard for the Control of Hazardous Energy (29 CFR 1910.147). Implementing OSHA’s lockout tagout standard ensures that employers develop a hazardous energy control program to keep employees safe from various types of hazardous energy release.

Why do employers need a hazardous energy lockout tagout program? The main reason is to maintain worker safety from the release of stored energy, including electricity, air, heat, water, chemicals, hydraulics, or any other type of energy that could cause injury. On top of that, the control of hazardous energy standard is consistently one of the top 10 most frequently cited OSHA standards. Keeping your lockout tagout program up to date helps maintain safety and prevent OSHA citations for failure to implement the requirements.

Hazardous Energy Lockout Tagout Requirements

Every lockout tagout program starts with a set of energy control procedures to prevent personal injury or property damage when working with, near, or on machines. Any employer, large or small, that has machines or equipment is required to follow the control of hazardous energy standard when the equipment needs maintenance. For each piece of machinery that could harm an employee when it is unexpectedly started without safety devices in place, there should be energy control procedures. A hazardous energy control procedure is a set of steps to manually add locks and tags to parts of the machine to prevent accidents and to make all employees aware of the ongoing maintenance work.

Elements of the Lockout Tagout OSHA Process

Whenever equipment needs to undergo maintenance or service, the hazardous energy lockout tagout procedure is set into motion. Equipment must be shut down, locked out, tagged, and rendered essentially non-operational to prevent an unexpected startup or release of hazardous energy.

What is the correct order for proper lockout procedures?

Regardless of the type of equipment, a maintenance related lockout tagout procedure follows these general steps:

- Identify the correct procedure for the equipment and prepare for the shutdown.

- Notify affected employees of the impending lockout.

- Shut down the equipment.

- Isolate energy sources, such as a circuit breaker or valve that supplies energy to the machine.

- Apply lockout devices and tags to energy sources.

- Release or control all stored energy such as compressed air, capacitors that hold an electrical charge, or compressed springs.

- Verify the lockout to make sure all hazardous energy has been isolated.

- Maintain the lockout until service can be restored.

Difference between lock out and tag out

In general, locks and tagout devices are used together when a piece of equipment is under maintenance. A lock is an energy isolating device that prevents the release of hazardous energy, and it must be assigned to a particular employee who is authorized to prevent access to the machinery. Depending on hazardous energy control procedures, more than one employee’s lock may be used to prevent access to equipment during maintenance.

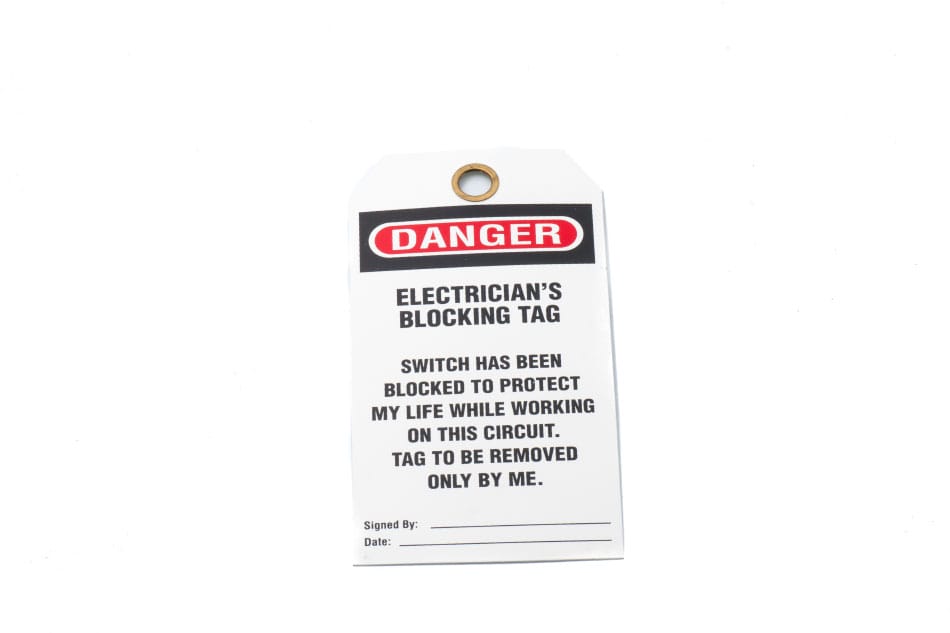

A tagout device is normally affixed to the lock to indicate the danger and the person responsible for removing the tag. In some limited circumstances, tagout devices can be used on their own as long as the employer can show that the tagout system alone provides full protection of employee safety and health.

How do you know if your energy control procedures are current?

Part of the lockout tagout standard requires a periodic review of procedures. Many employers perform a yearly review of all procedures to identify any changes to equipment, personnel, and duties that would require procedure changes or retraining.

Employee Training Requirements for LOTO

Taking a look at your equipment and processes to develop a lockout tagout program is only one part of the equation. As your machines or equipment change over time, your procedures change as well, including your lockout tagout procedures. Even if your energy control program has been in place for a long time, ongoing training is necessary to ensure up-to-date employee protection, while onboarding new employees or accounting for changing job roles.

For overall safety and health, all employees who are either performing maintenance or affected by the lockout tagout program should receive training.

- An authorized employee is a person whose job is servicing or maintenance of the affected equipment. They are responsible for implementing the lockout tagout of a particular machine or equipment, and they may be responsible for communicating as well.

- An affected employee is someone whose job is to operate or use equipment that is under lockout tagout and unavailable for use. Even employees who work in the area and may be prevented from accessing equipment need to be trained to understand the importance.

Even employees who are not affected by the hazardous energy lockout tagout procedures should be trained to be aware of lockout tagout program requirements if they work in the area.

The training needs of an authorized employee are different than the needs of an affected employee, given their different roles and responsibilities. For either role, lockout tagout training must cover at least three things:

- the employer’s energy control program

- elements of the energy control procedure related to the employee’s duties

- requirements of OSHA standards related to the lockout tagout program

Making sure your lockout tagout program is adequate

Programs to maintain worker safety and to control the release of hazardous energy are uniquely tailored to each employer. EMDS offers OSHA Lockout Tagout and Safety Consulting to assist your company in developing and implementing its own custom procedures. Consulting includes both energization and startup of machinery and equipment, and the release of hazardous energy during service or maintenance.

OSHA 10/30 compliance training helps to develop familiarity with the related OSHA standards and how to meet them, so you can develop lockout tagout procedures that work for your organization. EMDS offers an OSHA 10/30 compliance training course that covers the basics of occupational safety and health training and provides more detail explaining OSHA standards and requirements, including hazardous energy lockout tagout procedures. The training is offered in a virtual or in-person classroom, with plenty of examples and discussion.

Whether you update your training and procedures on your own or decide to get expert help, ensure the safety of employees and avoid OSHA citations by making sure your lockout tagout procedures are up to snuff.